Products

Products

Overview:

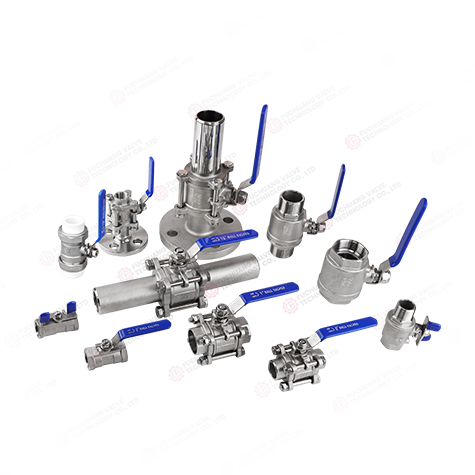

Threaded ball valves and flanged gate valves belong to the same type of valves. The difference lies in that the closing part of a threaded ball valve is a ball, which rotates around the centerline of the valve body to achieve opening and closing. Ball valves are mainly used in pipelines to cut off, distribute and change the flow direction of the medium. Two-piece and three-piece ball valves are a new type of valve that has been widely adopted in recent years.

Nominal diameter: DN15 - DN100

Nominal pressure: PN1.0 to PN6.4MPa

Manufacturing standards: GB, DIN, API, ANSI, BS, JIS, etc

Valve body material: carbon steel, stainless steel, alloy steel, ultra-low carbon stainless steel, titanium alloy, high-nickel alloy and Monel alloy, etc

Application:

The products are widely applied in many fields such as petroleum, chemical engineering, water conservancy, power stations, agriculture, medicine and food.

Overview:

The mini ball valve is mainly composed of the valve body, ball, valve stem, sealing parts, etc. The ball is the core component, forming a seal with the valve body. The valve stem is used to control the rotation of the ball, and the sealing element ensures the sealing performance of the valve. It achieves the opening and closing of the valve by rotating the sphere. When the sphere rotates 90 degrees, the fluid channel is fully opened and the fluid can pass through smoothly. When the sphere rotates to 180 degrees, the fluid channel is closed, achieving fluid blocking.

Nominal diameter: DN15 - DN32

Nominal pressure: PN1.0-4.0MPa

Operating temperature: -29 to 180℃ (with reinforced polytetrafluoroethylene sealing ring) / -29 to 300℃ (with para-polystyrene sealing ring)

Applicable media: water, steam, oil products, acetic acid and many other media

Power supply voltage: AC85V-260V, 3V-6V (DC), 9V-24V (AC or DC), 220V

Mechanical travel Angle: 0-90°

Connection methods: pipe thread (internal thread), external thread, ferrule, clamp, etc

Overview:

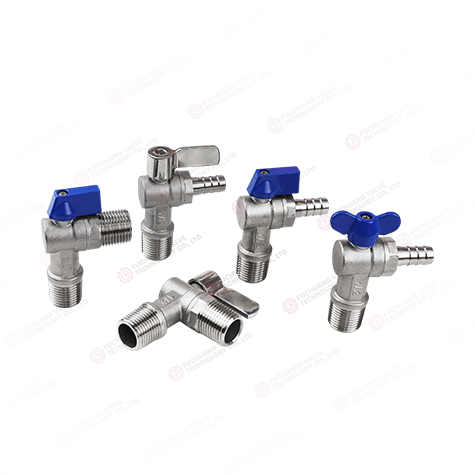

The Angle valve is also known as the Angle stop valve. Similar to the ball valve, its structure and characteristics are modified from the ball valve. The difference from the spherical valve lies in that the outlet of the Angle valve is at a 90-degree right Angle to the inlet. The Angle valve is also known as the triangular valve, the Angle valve or the folded Angle water valve. This is because the pipe forms a 90-degree corner shape at the Angle valve, so it is called an Angle valve, an Angle valve, or a folded Angle water valve. It is mainly applied to household water pipe equipment and is also widely used in industry.

Nominal diameter: DN15 - DN25

Nominal pressure: PN1.0, 1.6, 4.0, 6.4MPa

Connection thread dimensions: G1/2, G3/4, G1

Installation points:

Remove foreign objects from the connection parts before installation. When tightening the Angle valve, do it clockwise. When winding the raw material tape, do it counterclockwise. Make sure it is tightly attached to the thread. Wind it more than ten times to ensure a seal. Do not apply excessive force when tightening the thread.

Overview:

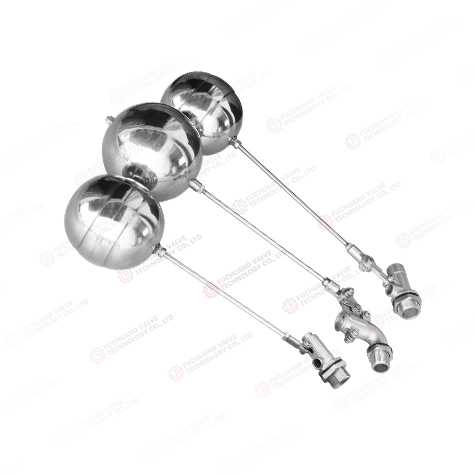

Valves composed of components such as articulated arms and float balls can be used to automatically control the liquid level in water towers or pools. It features simple maintenance, flexibility and durability, high accuracy of liquid level control, water level not disturbed by water pressure, and tight opening and closing without leakage.

Floating ball valves mainly have structural features such as valve seat sealing design, reliable reverse sealing valve stem, fireproof and static electricity function, automatic pressure relief and locking device, etc.

Nominal diameter: DN15 - DN100

Nominal pressure: PN1.0 to PN1.6MPa

Operating temperature: -20 ℃ to 200℃

Application field:

Floating ball valves are suitable for industries such as chemical engineering, petroleum, natural gas, metallurgy, etc., as well as long-distance natural gas pipelines containing hydrogen sulfide media, with many impurities and severe corrosion.

Overview:

A faucet, also known as a water spout, is a valve-type device usually used on water pipes. A faucet is a device that opens and closes the water medium and controls the water flow and temperature at the outlet. For the cold and hot water pipelines used in the kitchen of buildings, the nominal pressure shall not exceed 1MPa and the water temperature shall not exceed 90℃.

Control mode: Single handle single control, single handle double control, double handle double control and others

Valve body material: copper alloy, stainless steel, plastic and others

Nominal diameters: DN15, DN20, DN25

The pitch of the cold and hot water combined valve: 100mm, 150mm, 200mm

Sealing ring: PTFE

O-ring: Silicone

Applicable media: water, gas, etc

Threads: NPT, BSPT, BSPP

Overview:

A check valve is a type of valve where the fluid can only flow along the water inlet but the medium at the water outlet cannot flow back. It is commonly known as a check valve. A one-way valve is also known as a check valve or non-return valve. It is used in hydraulic systems to prevent the reverse flow of oil, or in pneumatic systems to prevent the reverse flow of compressed air. There are two types of check valves: straight-through and right-angle. The straight-through check valve is installed on the pipeline by threaded connection. There are three forms of right-angle check valves: threaded connection, plate connection and flange connection.

Nominal diameter: 21/16 "to 41/16"

Working pressure: 2,000-15,000PSI

Temperature: -60°C to +121°C(K,U)

Product specification level: PSL3~4

Product performance level: PR1-2

Material grade: AA - FF

Overview:

An exhaust valve is a device used to control the gas discharge in fluid systems. It is applied to the exhaust of pipelines in independent heating systems, centralized heating systems, heating boilers, central air conditioning, floor heating and solar heating systems, etc.

Nominal diameter: DN15 - DN25

Nominal pressure: PN10

Features:

◆ The float of the exhaust valve is made of low-density PPR and composite materials. This material will not deform even after being soaked in high-temperature water for a long time. It will not cause difficulties in the movement of the float.

◆ The float lever is made of hard plastic. The connections between the lever, the float and the support are all movable connections. Therefore, rust will not occur during long-term operation, which would cause the system to fail to work and result in water leakage.

◆ The sealing end face part of the lever is supported by a spring, which can extend and contract accordingly with the movement of the lever to ensure the sealing performance without venting.

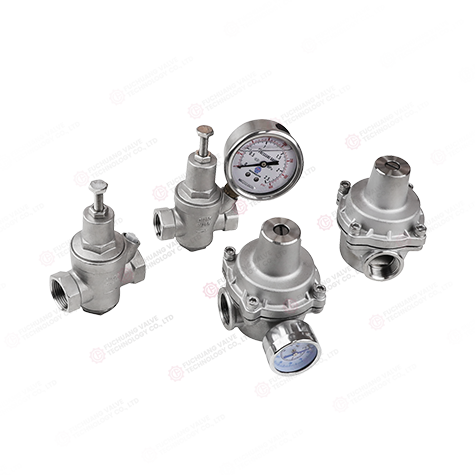

Overview:

A pressure reducing valve is a type of valve that reduces the inlet pressure to a required outlet pressure through adjustment and automatically maintains the outlet pressure stable by relying on the energy of the medium itself. From the perspective of fluid mechanics, a pressure reducing valve is a throttling element with variable local resistance. That is, by changing the throttling area, the flow velocity and the kinetic energy of the fluid are altered, resulting in different pressure losses and thereby achieving the purpose of pressure reduction. Then, through the regulation of the control and regulation system, the fluctuation of the pressure after the valve is balanced with the spring force, so that the pressure after the valve remains constant within a certain error range.

Nominal diameter: DN15 - DN200

Nominal pressure: 1.0MPa, 1.6MPa, 2.5MPa

Maximum inlet pressure: 16Mpa

Adjustable outlet pressure: 0.15-0.5Mpa

Working medium: Water

Maximum medium temperature: 80℃

Connection methods: threaded connection, flange connection, welding connection, etc

Overview:

High-platform ball valves and flanged gate valves belong to the same type of valves. The difference lies in that the closing part of a high-platform ball valve is a ball, which rotates around the centerline of the valve body to achieve opening and closing. Ball valves are mainly used in pipelines to cut off, distribute and change the flow direction of the medium.

Nominal diameter: DN15 - DN50

Nominal pressure: 1.6MPa

Suitable media: water, oil, gas

Suitable temperature: t≤150℃

Application:

The products are widely applied in many fields such as petroleum, chemical engineering, water conservancy, power stations, pharmaceuticals, construction, gas, fire protection, etc.

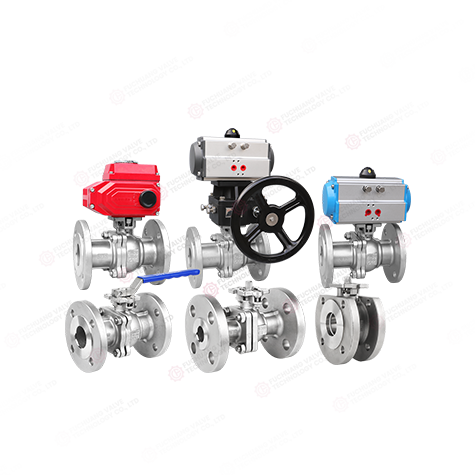

Overview:

Ball valves and gate valves belong to the same type of valves. The difference lies in that the closing part of a ball valve is a sphere, which rotates around the centerline of the valve body to achieve opening and closing. Ball valves are mainly used in pipelines to cut off, distribute and change the flow direction of the medium.

Nominal diameter: DN15-250

Nominal pressure: PN1.0-16.0MPa

Applicable media: water, gas, oil products, etc

Operating temperature: -196℃ to 540℃

Connection methods: flange, butt welding, threaded, socket welding, etc

Drive mode: Manual, worm gear and worm transmission, pneumatic, electric, hydraulic, pneumatic-hydraulic linkage, electro-hydraulic linkage

Application:

The products are widely applied in many fields such as petroleum, chemical engineering, power stations, natural gas, pharmaceuticals, food, water treatment, etc.

Overview:

Designed specifically for the food, pharmaceutical and other industries, it strictly controls the cleanliness standards and seamlessly meets the demands of hygienic production. It meets the high hygiene requirements of industries such as food and medicine, is fully sealed to prevent contamination, easy to clean and corrosion-resistant.

Nominal diameter: DN10-DN200

Working pressure: 1.0Mpa

Valve body material: SS304, SS304L, SS316, SS316L

Operating temperature: -10℃ to +150℃

Connection methods: Threaded, welded, quick installation, flange

Control methods: switch type, regulating type, manual control, pneumatic control, electric control

Overview:

An electromagnetic valve is an industrial device controlled by electromagnetism. It is an automated basic component used to control fluids and belongs to the actuator, not limited to hydraulics and pneumatics. It is used in industrial control systems to adjust the direction, flow rate, speed and other parameters of the medium. Solenoid valves can be combined with different circuits to achieve the expected control, and both the accuracy and flexibility of the control can be guaranteed. There are many types of solenoid valves, and different solenoid valves play different roles in different positions of the control system. The most commonly used ones are check valves, safety valves, directional control valves, speed control valves, etc.

Nominal diameter: DN15 - DN300

Nominal pressure: PN1.0MPa to PN50MPa

Features:

Compact in structure, small in size, light in weight, low in price, fast in action, low in power, high in reliability, easy to maintain, with good sealing when closed, the working fluid medium will not leak out of the valve, capable of separating the pressure-carrying fluid and the actuating electronic circuit, without the need for complex intrusive wiring or connection.

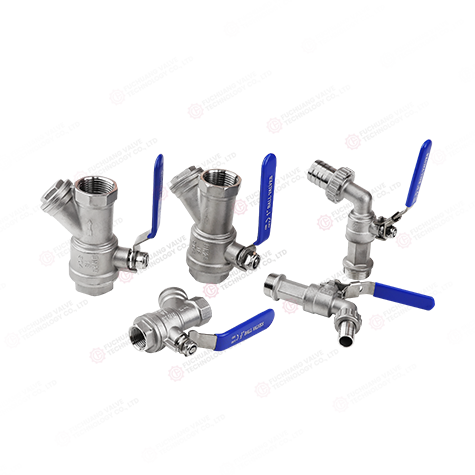

Overview:

Gate stop valves usually refer to gate valves, globe valves, check valves and filters, etc. They are control components in pipeline fluid transportation systems. They are used to change the cross-sectional area of the passage and the flow direction of the medium, and have functions such as guiding flow, cutting off, regulating, throttling, checking, diverting or overflow pressure relief.

Nominal diameter: DN15 - DN50

Nominal pressure: 1.0-1.6MPa

Suitable media: water, oil, gas

Suitable temperature: t≤150℃

Application:

The products are widely applied in many fields such as petroleum, chemical engineering, water conservancy, power stations, pharmaceuticals, construction, gas, fire protection, etc.